Stock ##

1 In Stock

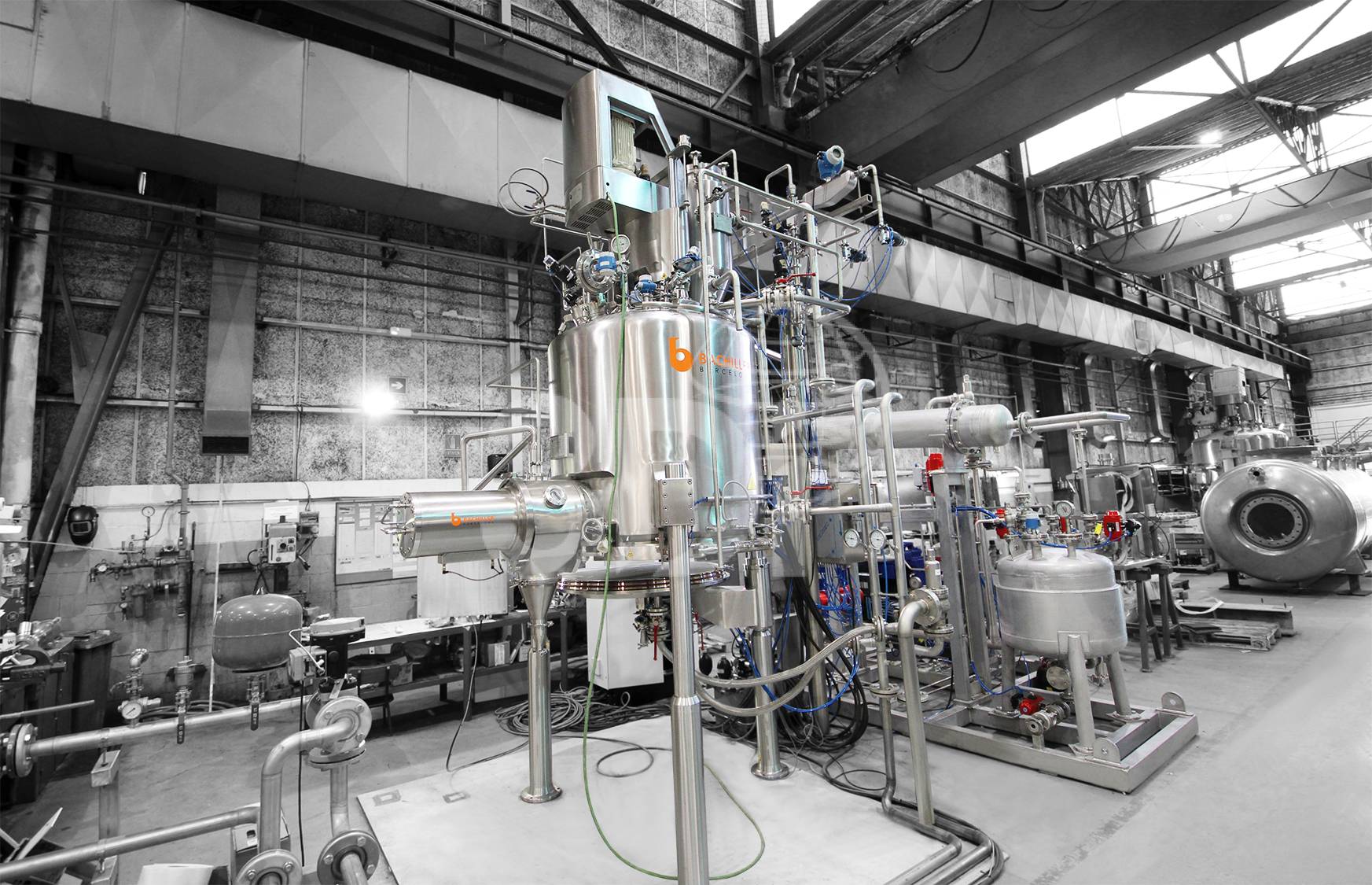

Nutsche Filters

Specification

Description

Nutsche Filters are closed, batch-operated filtration systems used for solid-liquid separation, particularly in the pharmaceutical, chemical, and fine chemical industries. They are designed to filter, wash, and sometimes dry wet cakes under pressure or vacuum, all in a sealed and contained vessel.

A Nutsche Filter:

- Filters slurries to separate solids from liquids,

- Uses vacuum or pressure to enhance filtration,

- Includes an agitator to mix, level, or reslurry the cake,

- Is a closed system, ideal for toxic, sterile, or sensitive materials.

| Component | Function |

|---|---|

| Filter vessel | Cylindrical vessel that holds the slurry. |

| Filter plate | Perforated support with a filter cloth or mesh that retains solids while allowing filtrate to pass. |

| Agitator | A shaft with blades that can move vertically and rotate to smooth, reslurry, or discharge the cake. |

| Drive system | Powers the agitator’s rotation and vertical movement. |

| Pressure or vacuum port | Enhances filtration and drying. |

| Discharge valve | For cake removal, often bottom-operated. |

- Slurry Charging: The slurry is pumped into the filter vessel.

- Filtration: Vacuum or pressure forces the liquid (filtrate) through the filter media, leaving a solid cake on top.

- Washing: Wash liquid is added and evenly distributed by the agitator to remove impurities from the cake.

- Drying (optional): Vacuum and agitation help remove residual solvent/moisture from the cake.

- Discharging: The agitator blades sweep the cake toward the bottom discharge valve.

- Closed system – safe for hazardous, toxic, or sterile materials.

- Multi-functionality – filter, wash, and dry in one vessel.

- Reduced product handling – minimizes contamination and material loss.

- Efficient washing – agitator enables full cake reslurrying and remixing.

- Gentle processing – ideal for fragile crystals or sensitive APIs.

- Pharmaceuticals – API filtration and washing.

- Agrochemicals – product purification.

- Specialty chemicals – dyes, pigments, catalysts.

- Biotech – protein or enzyme recovery.

- Battery materials & advanced materials – moisture-free processing.