Stock #

1 In Stock

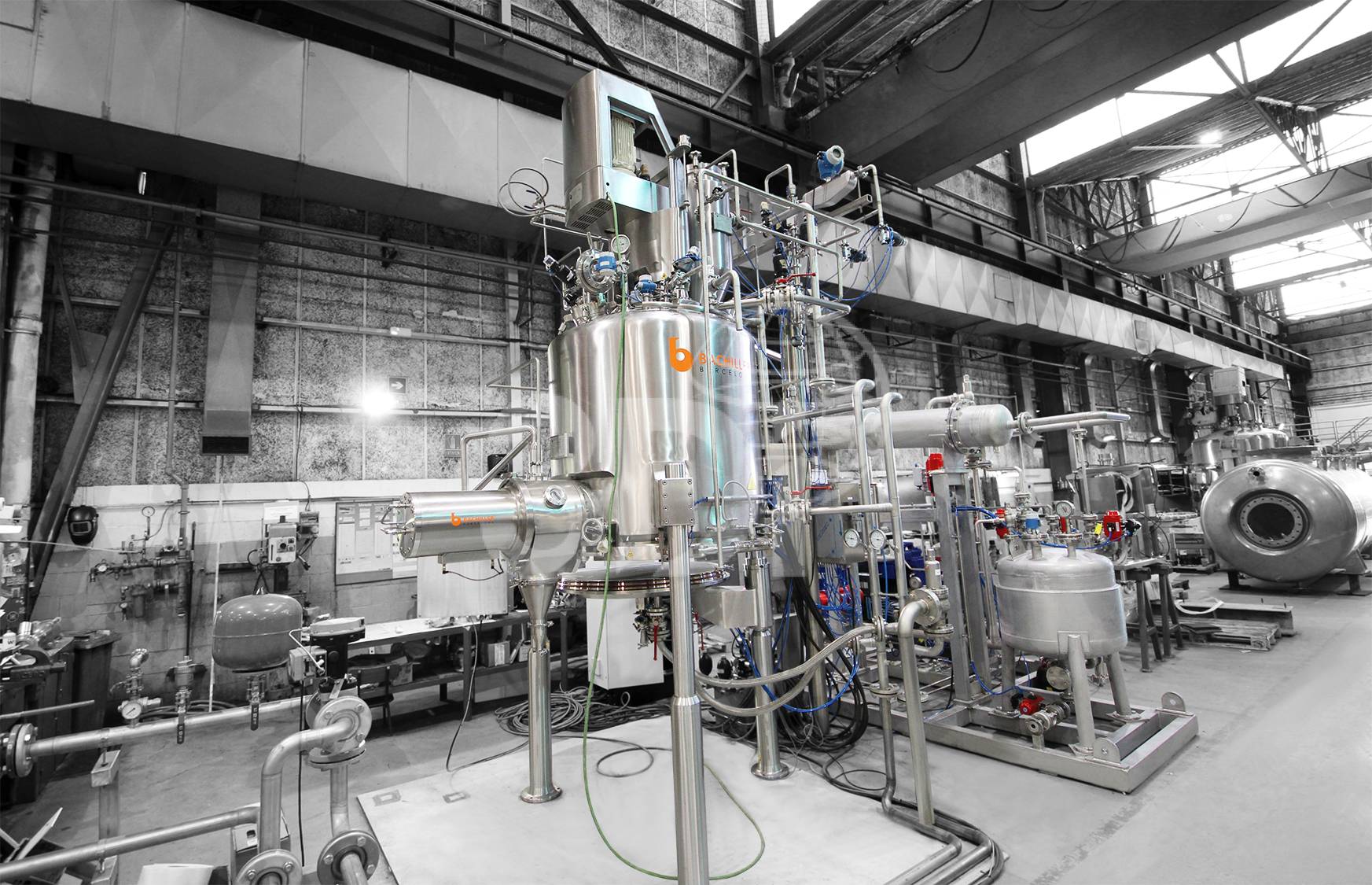

Nutsche Filters Dryers

Specification

Description

Nutsche Filter Dryers are multi-functional, closed-system industrial devices used for solid-liquid separation, washing, and drying of wet cakes—all in a single, sealed unit. It is especially suited for handling hazardous, sensitive, toxic, or valuable materials in industries such as pharmaceuticals, chemicals, food, and biotechnology.

A Nutsche Filter Dryer:

- Filters a slurry (solid-liquid mixture) to collect solids.

- Washes the collected solid (filter cake) to remove impurities.

- Dries the solid using heat and/or vacuum.

- Uses an agitator to aid in all of the above steps, ensuring uniformity and efficiency.

| Component | Function |

| Pressure-rated vessel | Contains the slurry and allows operations under vacuum or pressure. |

| Filter media | Retains solids, lets liquids pass through (e.g., sintered plate, cloth). |

| Agitator | Moves up/down and rotates; smooths, reslurries, breaks, and discharges the cake. |

| Heating jacket | Applies heat for drying via the vessel walls and/or agitator shaft/blades. |

| Vacuum/Pressure system | Enhances filtration and drying speed. |

| Discharge valve | Allows dried solids to exit with minimal manual handling. |

- Slurry Charging: Slurry is loaded into the sealed vessel.

- Filtration: Vacuum or pressure separates the liquid (filtrate) from the solid.

- Washing: Liquid wash is added; agitator mixes it with the cake for impurity removal.

- Drying: Heat (via jacket or agitator) and vacuum remove moisture or solvents.

- Discharge: Agitator moves down, scrapes, and pushes out the dry powder or cake.

- All-in-one system: No need to transfer material between filter, dryer, or washer.

- Closed system: Ideal for sterile or toxic processes (GMP-compliant).

- Improved drying efficiency: Agitator increases surface area.

- Reduced labour & exposure: Safer and more automated.

- Minimized material loss: Important for high-value substances.

- Pharmaceuticals (e.g., APIs)

- Fine chemicals

- Agrochemicals

- Biotechnology

- Food & nutrition