Stock #2865-1-1

1 In Stock

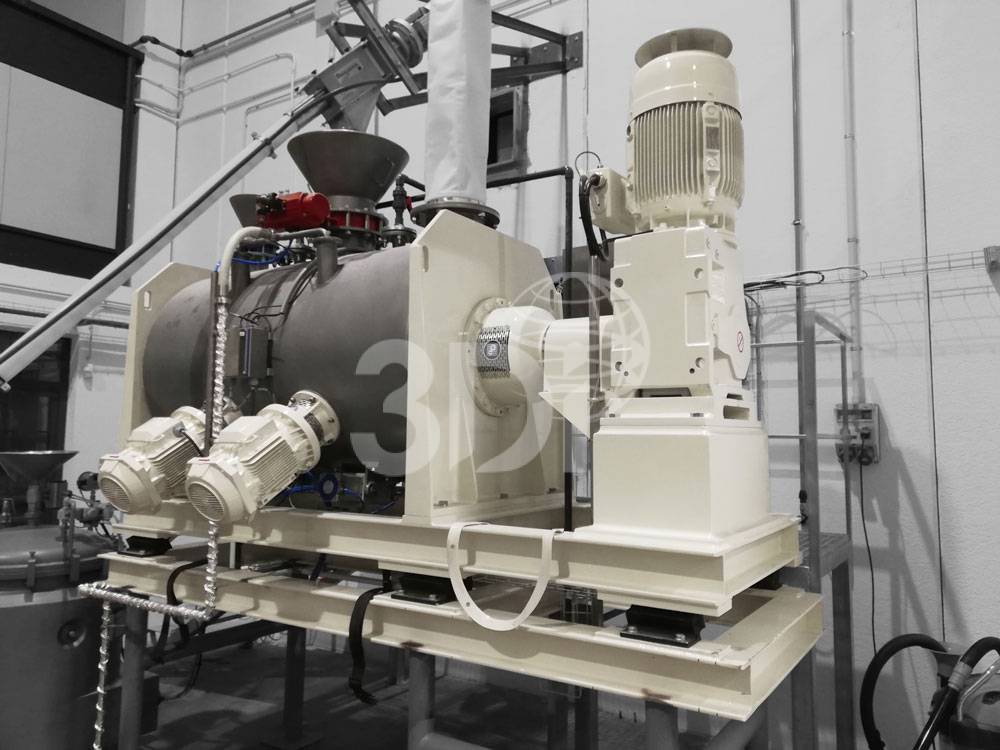

Paddle Dryer Reactor

Specification

Description

The Turbodry horizontal vacuum paddle dryer and reactor is designed for high-efficiency drying, mixing, and thermal processing of difficult, viscous, or pseudo-plastic materials—especially under vacuum or controlled atmospheres.

It combines indirect heating, intense agitation, and vacuum operation in a closed, sanitary system, making it ideal for industries like pharmaceuticals, fine chemicals, food, and cosmetics.

The Turbodry is specifically engineered to process materials that:

- Have pseudo-plastic behaviour (they become less viscous under shear),

- Require strong torque resistance,

- Need intense mixing and high turbulence during drying or reaction.

| Feature | Description |

| Horizontal cylindrical vessel | Offers excellent heat transfer surface and uniform mixing. |

| Vacuum-tight design | Enables low-temperature drying and solvent recovery. |

| Heated body, shaft, and paddles | Maximizes thermal efficiency by applying heat across all surfaces in contact with the product. |

| High-speed rotating paddles | Generate strong turbulence and shear forces, especially near the vessel walls, ensuring constant renewal of product surface in contact with heat. |

| High torque resistance | Allows processing of thick, sticky, or dense materials without stalling. |

| Closed, GMP-compliant system | Suitable for sterile, high-purity, or hazardous materials. |

- Charging: Wet cake, paste, or slurry is loaded into the chamber.

- Vacuum & Heating: The vessel, shaft, and paddles are all heated. Vacuum lowers the boiling point of moisture/solvent.

- Agitation: High-speed paddles create turbulence and shear, especially important for pseudo-plastic or non-Newtonian materials.

- Drying or Reaction: Moisture evaporates rapidly, or chemical reactions occur under controlled conditions.

- Discharging: The dry or reacted material is unloaded through a bottom outlet.

- Excellent heat transfer efficiency (due to full-surface heating and turbulence).

- Handles viscous or shear-sensitive materials with ease.

- Low-temperature drying protects heat-sensitive products.

- Solvent recovery under vacuum.

- Multi-functionality: drying, reacting, mixing in one unit.

- Closed system enhances product containment and safety.

- Pharmaceutical APIs and intermediates.

- Fine and specialty chemicals.

- Cosmetics and pastes.

- Food and nutraceuticals.

- High-viscosity polymers or reaction products.