Stock #2865-1-3

1 In Stock

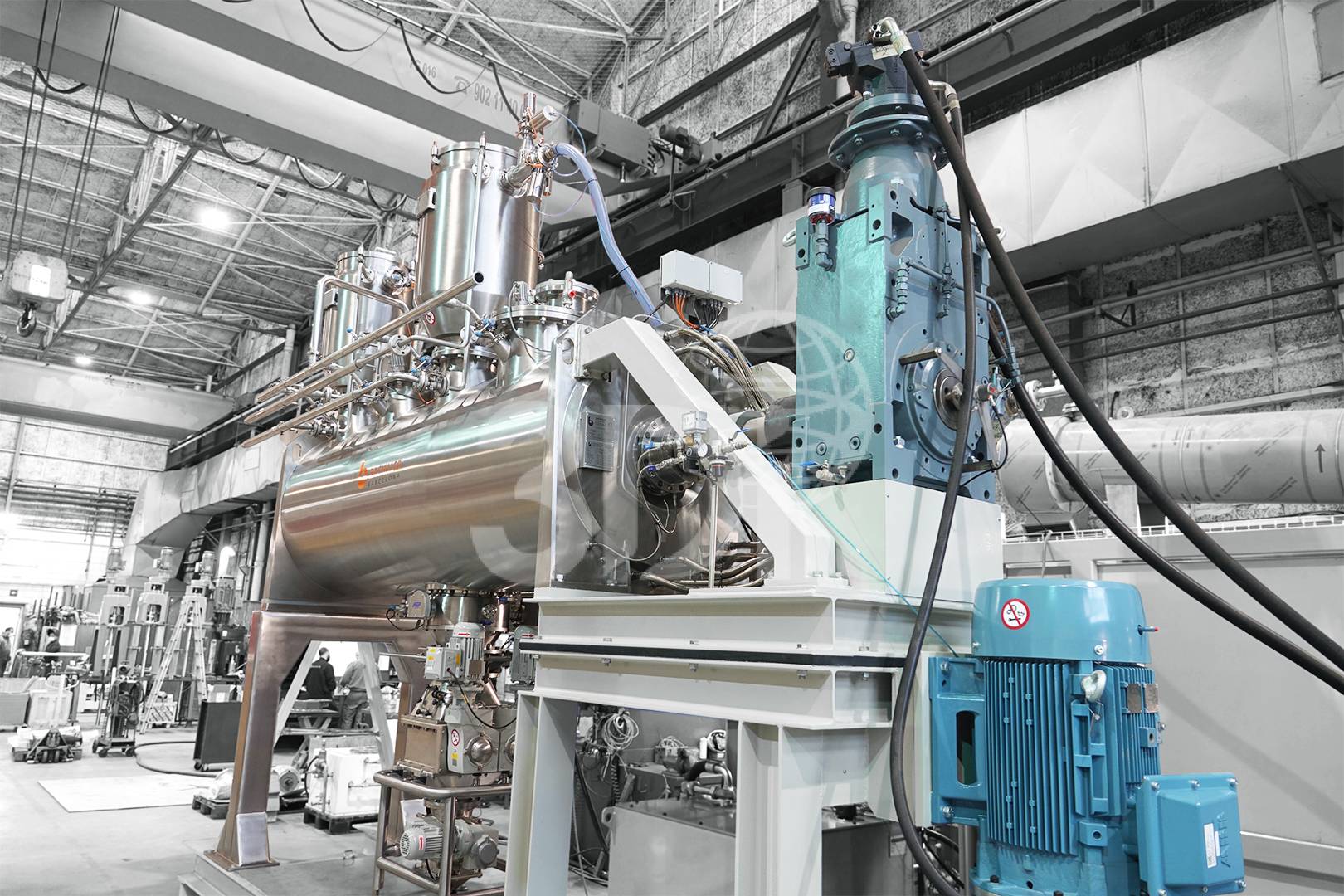

Horizontal Vacuum Paddle Dryer

Specification

Description

The PaddleDry Horizontal Vacuum Paddle Dryer is a batch drying system designed for efficient drying, mixing, and thermal processing of wet solids like slurries, pastes, or filter cakes—especially those that are sensitive to heat, oxygen, or shear.

Manufactured by companies like Bachiller, the PaddleDry combines indirect heat transfer, vacuum operation, and mechanical agitation using paddle-shaped mixing blades. It’s ideal for pharmaceuticals, chemicals, food ingredients, and waste treatment.

The PaddleDry is:

- A horizontal cylindrical vessel with an internal agitator fitted with paddles.

- Heated through a jacketed body and hollow shaft.

- Operated under vacuum to allow low-temperature drying.

- Designed for viscous, sticky, or pasty materials that are difficult to dry with traditional systems.

| Feature | Description |

| Horizontal chamber | Provides large surface area for heat transfer. |

| Agitator with paddles | Gently stirs and moves material to prevent buildup and ensure uniform drying. |

| Heated jacket + shaft + paddles | Maximizes indirect heat transfer from all surfaces in contact with product. |

| Vacuum-tight construction | Enables low-pressure operation for heat-sensitive products. |

| Solvent recovery system | Captures evaporated solvents through condensation. |

| GMP design (optional) | Mirror-polished internals, CIP/SIP, and pharma-grade components. |

- Loading: Wet product is loaded into the horizontal vessel.

- Heating & Vacuum: Heat is applied via jacket and internal components; vacuum lowers boiling point.

- Agitation: The rotating paddles move and mix the material, exposing wet surfaces and preventing clumping or hotspots.

- Drying: Moisture or solvents evaporate and are removed by the vacuum system and condenser.

- Discharging: Dried product is discharged through a bottom valve or side outlet.

- Efficient and uniform drying, even for sticky or dense materials.

- Low-temperature operation protects sensitive compounds.

- Closed system minimizes contamination, oxidation, and solvent loss.

- Multi-functional – can be used for drying, mixing, reacting, or sterilizing.

- High thermal efficiency due to large heated surface area (body + shaft + paddles).

- Pharmaceutical APIs and intermediates

- Fine and specialty chemicals

- Food and nutraceutical pastes or powders

- Polymer and resin drying

- Toxic or flammable solvent removal

- Sludge and waste treatment